Coronavirus PPE: Gowns ordered from Turkey fail to meet safety standards

GETTY IMAGES

GETTY IMAGES

Some 400,000 surgical gowns ordered from Turkey do not meet British safety standards, the UK government has said.

Up to half of the personal protective equipment (PPE) order was flown to the UK by the RAF last month, but has not been given to NHS workers and is now stuck in a warehouse.

It is not clear if the government will seek a refund from the suppliers.

The Department of Health said it was working "night and day to source PPE".

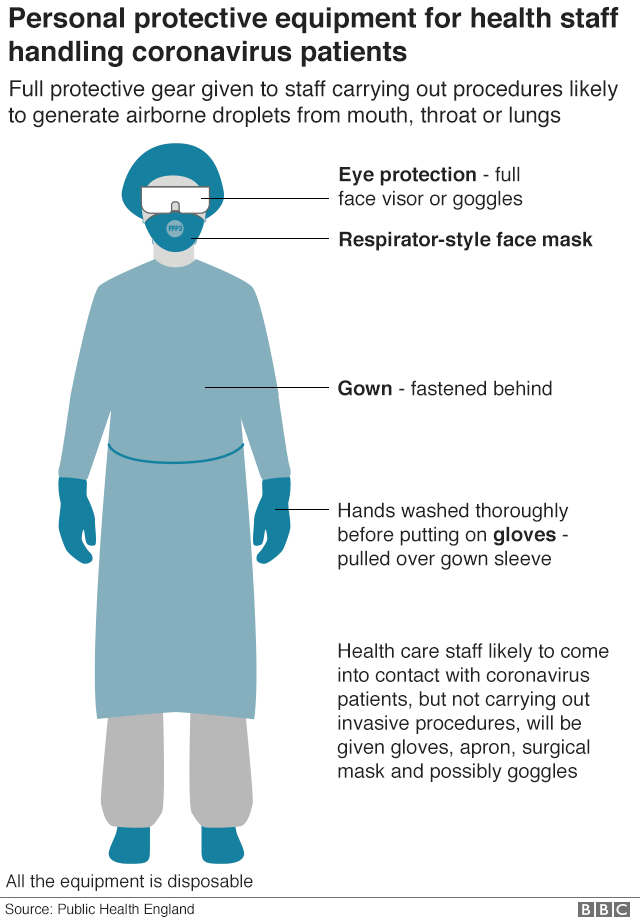

During the past few months as the UK has tackled the coronavirus pandemic, healthcare workers including doctors and nurses have complained of a lack of adequate kit such as gowns, masks and gloves.

PPE is essential for protecting front-line workers exposed to Covid-19, and without it workers are concerned they could catch or spread the virus.

Amid a row over the procurement of PPE in April, the government announced it had managed to source a large supply from Turkey.

After several delays, the RAF was deployed to Istanbul to fly it back to RAF Brize Norton on 22 April.

It is not known how much PPE was on board but the aircraft which was used can carry about 40 tons of cargo - about half of the consignment.

But now the government has confirmed that all of the surgical gowns that were delivered were unusable because they did not meet the required criteria.

The news was first reported by the Daily Telegraph.

Northern Ireland Secretary Brandon Lewis said it was "reassuring" that British experts were "ensuring the best quality of equipment".

He told BBC Breakfast that the government was "working through" a list of about 10,000 UK-based firms which have offered to make PPE, and had received 250,000 gowns from Northern Ireland.

PA WIRE

PA WIRE

Some NHS organisations have turned to local suppliers to get much-needed PPE. However, last week, the Department of Health called on hospitals to rely on the government's national procurement scheme to help ensure NHS Trusts did not "compete with each other for the same supplies".

The chief executive of the NHS Confederation, which represents health and care leaders, told the BBC that supplies were now "generally better" in hospitals but that care homes and GP surgeries still face "some difficulties".

Niall Dickson said that government needs to ensure "the rhetoric is matched by the reality on the ground" and that problems with the order from Turkey may encourage some NHS organisations to continue using their trusted local suppliers.

In a statement, the Department of Health and Social Care said there were shortages of PPE around the world, not just in the UK.

"We are working night and day to source PPE internationally and domestically and brought together the NHS, industry and the armed forces to create a comprehensive PPE distribution network to deliver critical supplies to the frontline," a spokesperson said.

"All deliveries of PPE are checked to ensure the equipment meets the safety and quality standards our frontline staff need. If equipment does not meet our specifications or pass our quality assurance processes it is not distributed to the front line."

5.6德國之聲向德國聯邦衛生部求證。該部的發言人瑙博爾(Teresa Nauber)證實:確實有大約20%來自中國的口罩"與標準不符"。但她明確指出:"這不意味著這些口罩無法醫用。"

4.26

需求大增之下,中國醫療用品市場陷入混亂 |

中國再次改變醫療物資出口規定

|

中國再次改變了對N95呼吸器、外科口罩、呼吸機、紅外體溫計和其他醫療用品的出口規定。這稍微放鬆了相關物資出海的難度,但也讓進口商承擔了更多的質檢責任。

|

此前,在歐洲國家和加拿大抱怨中國出口產品存在質量問題後,北京方面加強了防疫物資出口的監管,並要求醫療用品只有在符合中國質量技術標準的情況下才能出口。這導致數百萬套病毒檢測設備和其他設備在工廠和機場積壓。

|

但中國商務部、海關和市場監管當局週六實施的新規放寬了這一要求,符合國外認證標準的醫療物資生產企業也將被允許出口。但該規定首次要求海外進口商承擔質檢責任,對於非醫用口罩,企業報關時必須提交出口方和進口方的共同聲明,對產品質量及用途進行確認。

|

對此,渥太華一家貿易諮詢公司表示,北京官員“不想為假冒或有缺陷的產品承擔任何責任”。

|

***4.15

當武漢肺炎(COVID-19)蔓延全球之際,中國趁著本土疫情趨緩,開始對外輸出快篩盒、口罩等醫療物資,卻頻被各國發現品質不合格。根據中國媒體《21世紀經濟網》報導指出,這些劣質口罩以低價且防護效果極差的熔噴布充當高價品混充,不但一星期就可以回本,也連帶導致丙烯產業鏈受到影響。

除了被各國不斷批評買到中國製造品質不合格的口罩外,《21世紀經濟網》也報導中國劣質口罩問題不斷浮現,包括北京查扣12萬隻劣質口罩,湖北仙桃也銷毀了100多萬個不合格口罩。

劣質口罩過濾效果僅40%-50%

報導指出,在疫情帶動市場需求下,廠商以價格便宜的普通聚丙烯纖維料來取代熔噴級的纖維料,並以30萬元一台的小型熔噴機取代要價近千萬的專業熔噴布設備,最後生產出來的就是過濾效率只有40%-50%的熔噴布。

報導指出,劣質熔噴布的PP纖維料每噸7000元(人民幣,以下均同),熔噴級PP每噸要6萬元,且還買不到,即便買得到,現在價格也已漲到每噸8萬,讓一些小工廠嫌太貴改用纖維料。

即便是纖維料現在也已從每噸7000元漲到每噸2.5萬元人民幣,但相比每噸8萬元的專用料,還是有價格上的優勢。生產1噸熔噴布需要1.5噸的原料。根據中國券商研究員透露,這些劣質熔噴布之後可以用每噸35至60萬元的價格出售。報導還估計,若一開始投入設備30萬,再使用每噸3.75萬的纖維料,日產200公斤熔噴布,產品價格依照每噸35萬計算,這1個星期回本不是夢。

套利空間仍在 鋌而走險者眾

報導透露,到4月14日為止,還有人在網路採購平台上兜售熔噴布生產線,每套價格在30到40萬不等,還包教包會,交貨期可縮短至20天,至於原料則可以採用聚丙烯普通纖維料代替,依舊有利可圖。

報導表示,這些偷工減料生產出來的熔噴布,纖維更粗、阻隔效果更差,無法達到正規熔噴布的防護效果,同時因未進行駐極處理,熔噴布也少了靜電吸附的功能,網孔就有捕鯊魚和捉泥鰍的差別,防護力可見一般。

正由於中國廠商不斷投入劣質口罩生產,導致過去一段時間,劣質熔噴布的大量生產影響了整個丙烯產業鏈,過去熔噴布等原料對聚丙烯產業影響不大,但當廠商大肆投入生產纖維料之後,也讓聚丙烯價格水漲船高,影響了供應鏈。

沒有留言:

張貼留言